Abstract

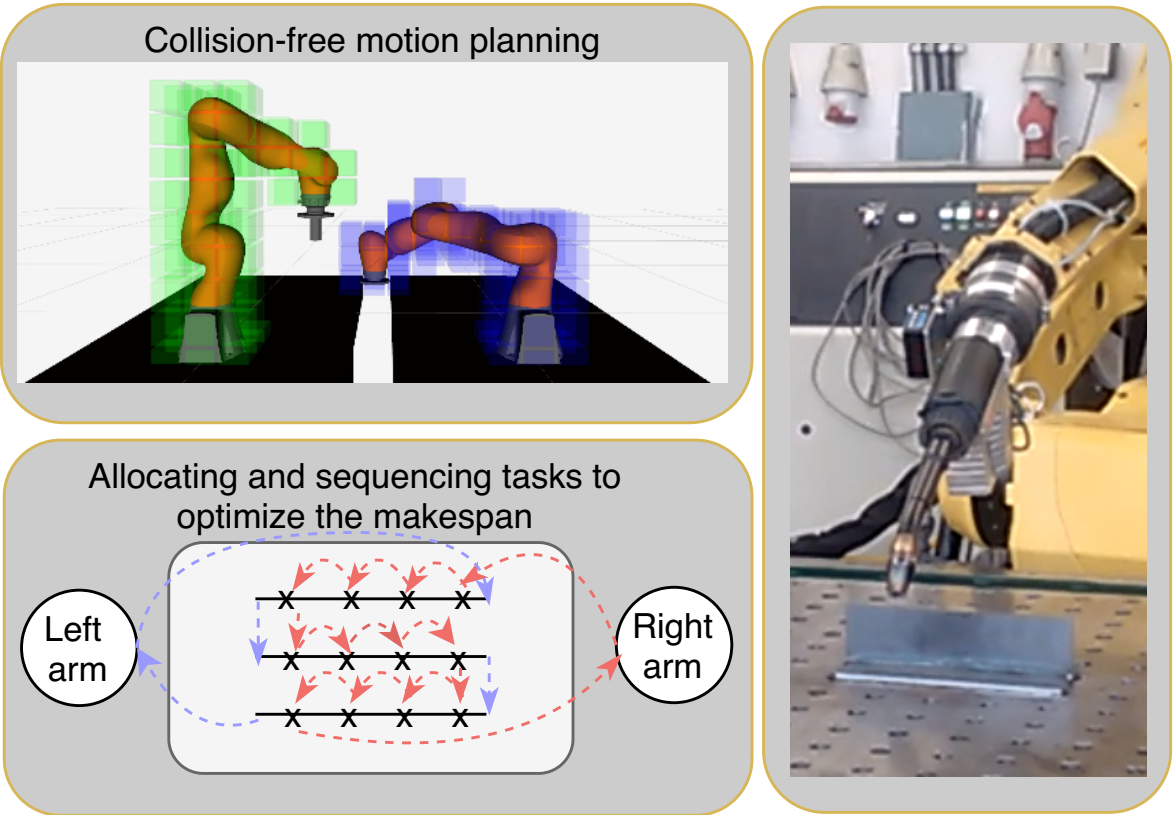

Coordination of multiple robots operating simultaneously in the same workspace requires the integration of task scheduling and motion planning. We focus on tasks in which the robot's actions are not necessarily confined to small volumes, but can also occupy a large time-varying portion of the workspace, such as in welding along a line or drilling a hole. Optimization of such tasks presents a considerable challenge mainly due to the fact that different variants of action execution exist, for instance, there can be multiple starting points of lines or closed curves, different filling patterns of areas, etc. We propose a generic and computationally efficient optimization method which is based on constraint programming. It takes into account the kinematics of the robot and guarantees that the motion trajectories of the robots are collision-free while minimizing the overall makespan. We evaluate our approach on several tasks of varying complexity: cutting, additive manufacturing, spot welding, inserting and tightening bolts, performed by a dual-arm robot. In terms of the makespan, the result is superior to task execution by one robot arm as well as by two arms not working simultaneously.